The details and common specifications of the magnetic grates(magnetic grids)

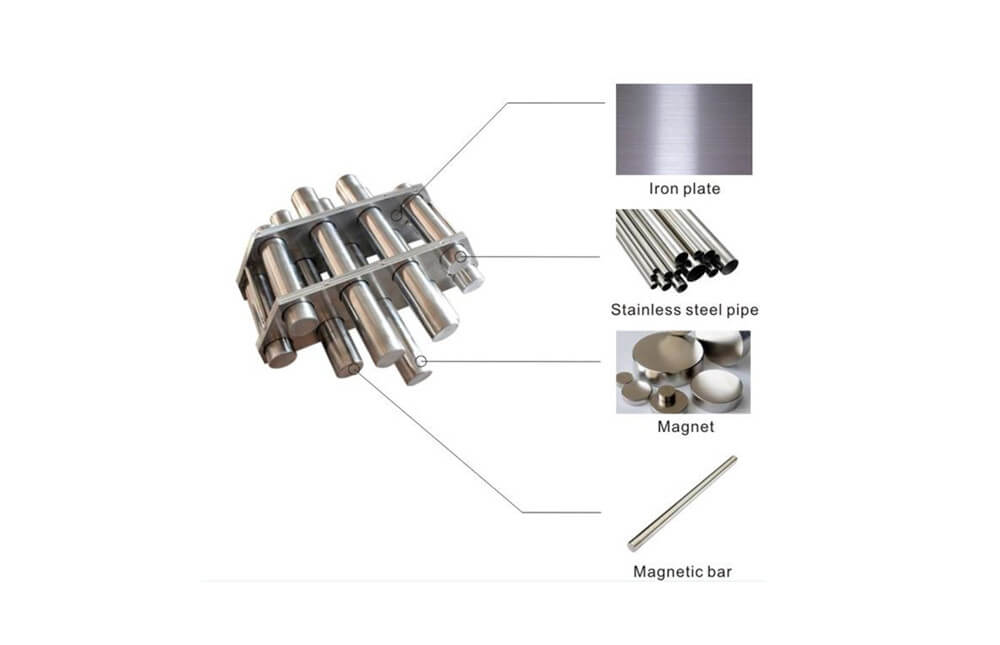

The magnetic grate(magnetic grid) is mainly used to remove iron impurities from the hopper, feed trough and floor space, which can effectively remove free flowing powder and iron impurities in small particles. The magnetic grate(magnetic grid) is equipped with a beautifully shaped and reasonably distributed magnetic bar that provides a high-intensity magnetic field to attract iron powder, iron filings, and other magnetically small pieces of metal in the flowing material.

The stainless steel seamless tube and the outer frame form a solid whole through the skilled welding of the workers. It can be installed on the production line or simply placed in a hopper, material box and easily removed and cleaned. The Sinoneo magnetic grate(magnetic grid) is made of materials with a corrosion-resistant surface that meets the cleanliness of food and even pharmaceuticals. Our magnetic grate(magnetic grid) is usually arranged in parallel with a center-to-center spacing of 50mm with a diameter 25mm magnetic bar.

The application of magnetic grate(magnetic grid):

Magnetic filter holder (magnetic frame) is mainly used to filter ferromagnetic impurities in powdery, granular raw materials and liquids or slurries. It is widely used in ceramics, electric power, mining, plastics, chemicals, rubber, pharmaceuticals, food, environmental protection, pigments. , dyes, electronics, metallurgy and other industries.

The working principle of magnetic grate(magnetic grid):

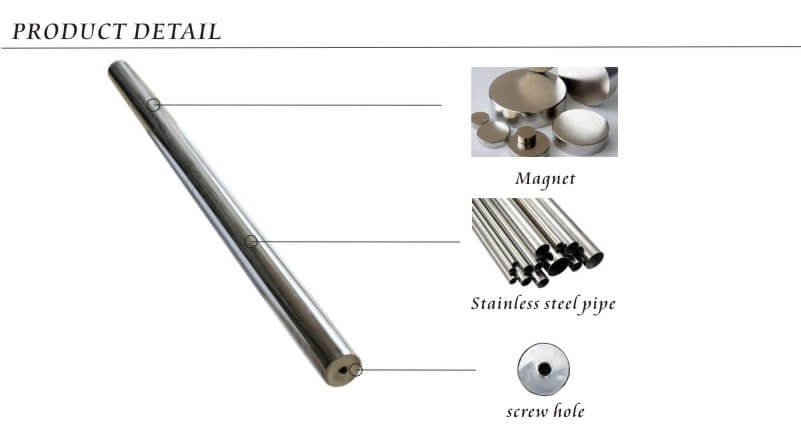

The magnetic filter grate(grid) is made of stainless steel tube and high value rare earth alloy NdFeB magnets. And combined on a fixed frame to form a magnetic filter holder. When the iron-containing substance passes, it is attracted by the magnetic rod, and the iron-containing substance is firmly adsorbed on the pipe wall to ensure the integrity of the equipment and the cleanness of the product.

The features of magnetic grate(magnetic grid):

The magnetic frame has no energy consumption and can be installed at any position on the production line that can be in contact with materials. It saves space and is easy to install. It mainly uses rare earth neodymium magnets as magnetic source, good magnetic force, simple structure and long working life. The style,size and shape can be customized according to customer requirements and production conditions.

The magnetic filter frame is mainly used to remove iron impurities from the hopper, feed trough and floor space, which can effectively remove free flowing powder and iron impurities in small particles. The magnetic grate(magnetic grid) has a well-packaged magnetic bar that provides a high-intensity magnetic field to attract iron powder, iron filings, and other magnetically small pieces of metal in the flowing material. It can be installed on the production line or simply placed in a hopper, material box and easily removed and cleaned.

The common specifications of magnetic grate(magnetic grid):

Single layer of pipe (9 pipe double layer) 300 x 40 (80) 6 pipe single layer (11 pipe double layer) 300 x 300 x 40 (80) 6 pipe single layer (11 pipe double layer) 350 x

40 (80) 7 single layer (13 tubes double layer) 350 x 350 x 40 (80) 7 tube single layer (13 tubes double layer) 400 x 40 (80) 8 tube single layer (15 tube double layer) 400 x 400 x 40 (80) 8 tube single layer (15 tube double layer) 450 x 40 (80) 9 tube single layer (17 tube double layer) 450 x 450 x 40 (80) 9 tube single layer (17 tube double layer) 500 x 40 (80) 10 tube single layer (19 tube double layer) 500 x 500 x 40 (80) 10 tube single layer (19 tube double layer)