Posts

How to Solve The Iron Slag Troubles For You?

The material will be mixed with a lot of iron impurities, which has become a headache for the manufacturers. To solve the problem of iron filings, Sinoneo magnetic bar providing reliable iron slag solutions and tailoring various strong magnetic bars.

The headache of the manufacturer is that the material is not clean and the product can not pass the quality inspection. This is a common problem.

This is the pain point of the manufacturers mentioned at the beginning of this article. Every time the iron products removed from the purchase can not filter the iron slag, the product can not pass the quality inspection, how to change the situation,so that It can reduce the production cost and quickly solve the problem.

It is necessary to mention the key points, how to find a good magnetic filter bar manufacturer!

Purchasing a strong magnetic bar not only depends on the price, but also on the quality! The low-priced strong magnetic bar, the magnet with the refurbished magnetic material or the magnetic core is not the same size, the strong NdFeB magnet is replaced by the ferrite magnet, which leads to the price of magnetic bar is different on the market.

How do you know the difference between good and bad magnetic bars?

Sinoneo Magnets magnetic bar manufacturers master to give you some suggestions:

First, starting from the appearance, how to weld the two ends of the magnetic bar, whether there is strict welding, can not enter the water, if found to be able to enter the water phenomenon, which means that this magnetic bar is not a good magnetic bar, can not be used.

Second, starting from the magnetic line, holding the magnetic rod to roll a few times in the ground, the magnetic line will come out, then you can use the Gauss meter to measure the magnetic force, confirm if you can meet your requirements.

Third, starting from the size of the specifications, using a special tool to measure the diameter of the strong magnetic bar has not reached the size of the order at the time, the deviation is not serious, these all indicate the strength of the manufacturer and the attitude of doing things.

Once you know this, go and tell your company’s purchasing staff, you have the ideas to reduce production costs and make the materials more pure.

Strong magnetic rod manufacturers: Sinoneo magnets focus on providing filter iron slag solutions, let us help you!

The details and common specifications of the magnetic grates(magnetic grids)

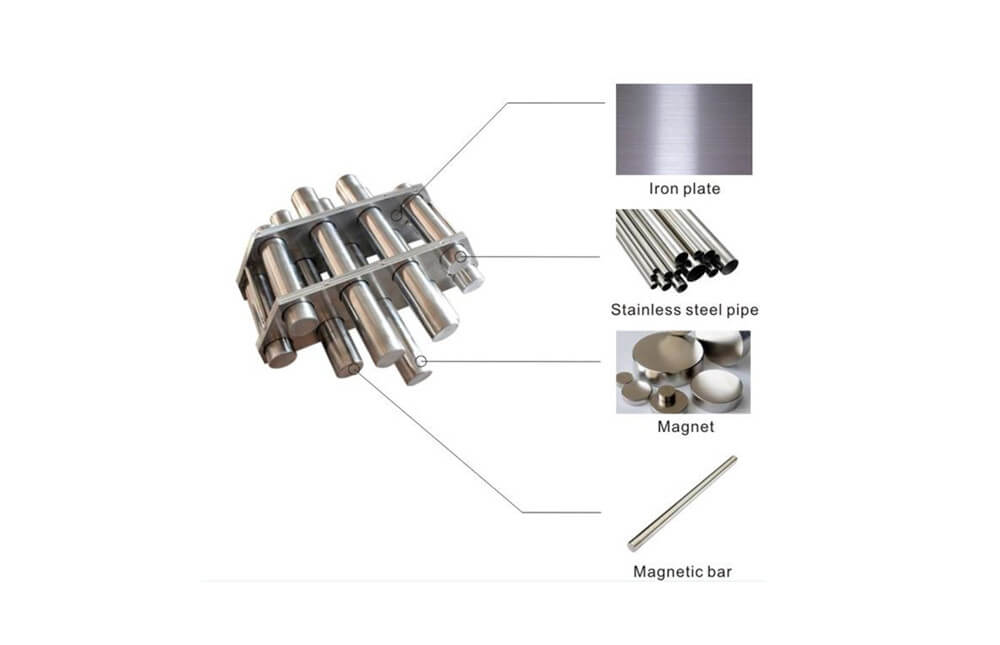

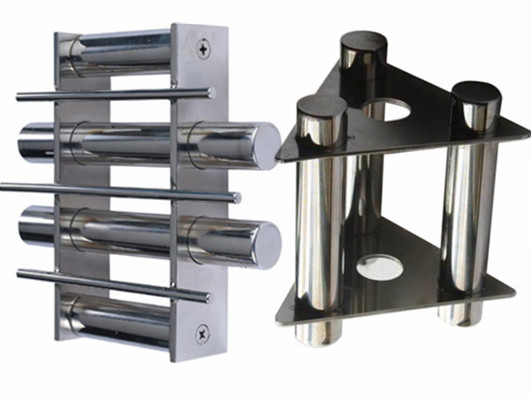

The magnetic grate(magnetic grid) is mainly used to remove iron impurities from the hopper, feed trough and floor space, which can effectively remove free flowing powder and iron impurities in small particles. The magnetic grate(magnetic grid) is equipped with a beautifully shaped and reasonably distributed magnetic bar that provides a high-intensity magnetic field to attract iron powder, iron filings, and other magnetically small pieces of metal in the flowing material.

The stainless steel seamless tube and the outer frame form a solid whole through the skilled welding of the workers. It can be installed on the production line or simply placed in a hopper, material box and easily removed and cleaned. The Sinoneo magnetic grate(magnetic grid) is made of materials with a corrosion-resistant surface that meets the cleanliness of food and even pharmaceuticals. Our magnetic grate(magnetic grid) is usually arranged in parallel with a center-to-center spacing of 50mm with a diameter 25mm magnetic bar.

The application of magnetic grate(magnetic grid):

Magnetic filter holder (magnetic frame) is mainly used to filter ferromagnetic impurities in powdery, granular raw materials and liquids or slurries. It is widely used in ceramics, electric power, mining, plastics, chemicals, rubber, pharmaceuticals, food, environmental protection, pigments. , dyes, electronics, metallurgy and other industries.

The working principle of magnetic grate(magnetic grid):

The magnetic filter grate(grid) is made of stainless steel tube and high value rare earth alloy NdFeB magnets. And combined on a fixed frame to form a magnetic filter holder. When the iron-containing substance passes, it is attracted by the magnetic rod, and the iron-containing substance is firmly adsorbed on the pipe wall to ensure the integrity of the equipment and the cleanness of the product.

The features of magnetic grate(magnetic grid):

The magnetic frame has no energy consumption and can be installed at any position on the production line that can be in contact with materials. It saves space and is easy to install. It mainly uses rare earth neodymium magnets as magnetic source, good magnetic force, simple structure and long working life. The style,size and shape can be customized according to customer requirements and production conditions.

The magnetic filter frame is mainly used to remove iron impurities from the hopper, feed trough and floor space, which can effectively remove free flowing powder and iron impurities in small particles. The magnetic grate(magnetic grid) has a well-packaged magnetic bar that provides a high-intensity magnetic field to attract iron powder, iron filings, and other magnetically small pieces of metal in the flowing material. It can be installed on the production line or simply placed in a hopper, material box and easily removed and cleaned.

The common specifications of magnetic grate(magnetic grid):

Single layer of pipe (9 pipe double layer) 300 x 40 (80) 6 pipe single layer (11 pipe double layer) 300 x 300 x 40 (80) 6 pipe single layer (11 pipe double layer) 350 x

40 (80) 7 single layer (13 tubes double layer) 350 x 350 x 40 (80) 7 tube single layer (13 tubes double layer) 400 x 40 (80) 8 tube single layer (15 tube double layer) 400 x 400 x 40 (80) 8 tube single layer (15 tube double layer) 450 x 40 (80) 9 tube single layer (17 tube double layer) 450 x 450 x 40 (80) 9 tube single layer (17 tube double layer) 500 x 40 (80) 10 tube single layer (19 tube double layer) 500 x 500 x 40 (80) 10 tube single layer (19 tube double layer)

What’s the difference between Alnico, Sm-Co & Nd-Fe-B magnet materials?

Alnico is an older magnet material that still has important applications. Its maximum energy product is about 1/5 of Sm-Co materials, but it has excellent elevated temperature properties and has better corrosion resistance.

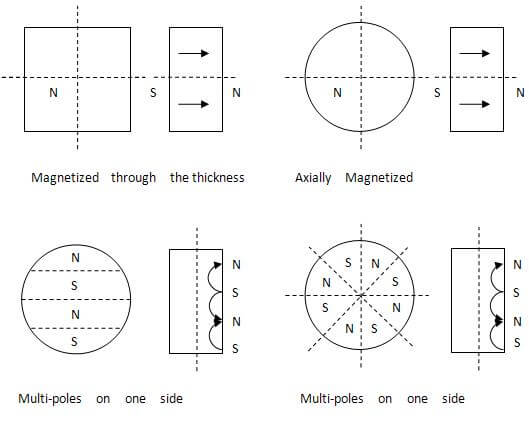

Alnico can be cast into different shapes with various magnetic orientations. The rare earth Sm-Co and NdFeB magnets have high coercivity, so they do not need to be magnetized in circuit and can be used with low permeance coefficients (i.e. thin discs).

These materials also lend themselves to Helmholtz coil testing due to their straight line normal curves. This also makes rare earths ideal for SMC and high field dipoles. Sm-Co has a good resistance to thermal demagnetization but is brittle.

NdFeB is less brittle, has poor thermal properties, and is prone to corrosion.

What are neodymium magnets? Are they the same as “rare earth”?

Neodymium magnets are a member of the rare earth magnet family. They are called “rare earth” because neodymium is a member of the “rare earth”elements on the periodic table. Neodymium magnets are the strongest of the rare earth magnets and are the strongest permanent magnets in the world.

Which is the strongest type of magnet?

Neodymium (more precisely Neodymium-Iron-Boron) magnets are the strongest permanent magnets in the world.Neodymium magnets are a member of the Rare Earth magnet family and are the most powerful permanent magnets in the world.

They are also referred to as NdFeB magnets, or NIB, because they are composed mainly of Neodymium (Nd), Iron (Fe) and Boron (B). They are a relatively new invention and have only recently become affordable for everyday use.

What does the “N rating”, or grade, of the neodymium magnets mean?

The grade, or “N rating” of the magnet refers to the Maximum Energy Product of the material that the magnet is made from. It refers to the maximum strength that the material can be magnetized to. The grade of neodymium magnets is generally measured in units millions of Gauss Oersted (MGOe). A magnet of grade N42 has a Maximum Energy Product of 42 MGOe. Generally speaking, the higher the grade, the stronger the magnet.