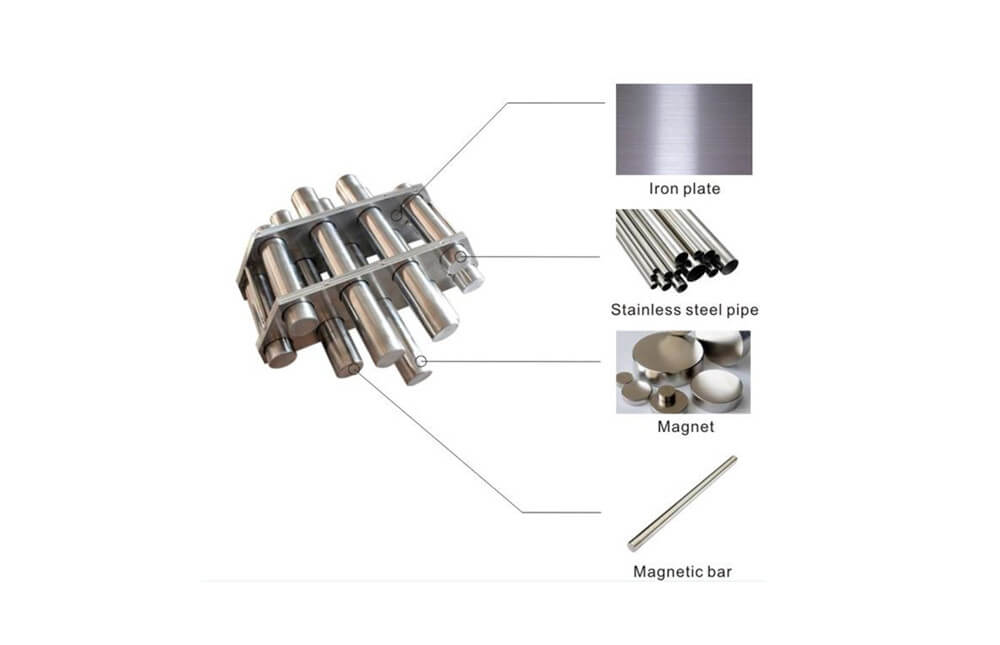

Strong magnetic bar is a production equipment that guarantees the safety and quality of products. The ceramic industry and the food industry have been widely used and become one of the production equipments. The strong magnetic rod used in the pharmaceutical and food industries is a permanent magnet magnetic rod that does not require a power source.

The basic principle is that when the iron-containing substance passes, it is attracted by strong magnetic force, and the iron-containing substance is firmly adsorbed on the pipe wall to ensure the integrity of the equipment and the safety of the product.

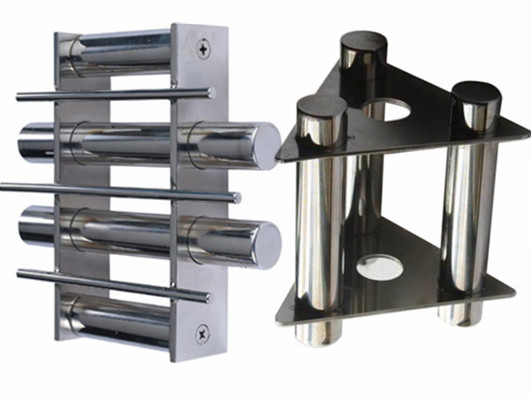

Divided from the structure, there are two kinds of strong magnetic rods, one is the process equipment connected with other production equipment, such as pipe iron remover, mixed iron remover, etc., the structure is relatively simple; one is the whole machine, such as rotary iron remover, Light powder iron remover. In addition, complete machines with composite functions, such as granulation and iron removal machines, screening and iron removal machines, etc., have appeared on the market.

From the technical function, the magnetic bar has a high, medium and low grade. The magnetic rod iron remover for assembling the magnetic rod with the ferrite magnetic material has the function of removing the ferromagnetic metal foreign matter, and the price is low, which is a low grade.

The magnetic rod is made of rare earth magnetic material, namely neodymium iron boron. NdFeB is divided into different series and grades according to its function. Mid-range iron remover generally uses N48 below NdFeB magnetic material, its field peak is 7000 to 10000 Gauss; Gaussian strong magnetic rod uses N48H, N50 or more magnetic material, the peak value of the table is as high as 12000 Gauss.

Magnetic bars are different from metal detectors. The strong magnetic rod is superior to the latter in that it can remove metal foreign matter in the production process, and the removal method is superior. In order to ensure the safety and quality of products, many large-scale enterprises use both products at the same time.

The selection of strong magnetic rods should be based on the actual and applicable cost requirements. First, it is necessary to determine whether to select process equipment or the whole machine according to the actual conditions of production;

Second, you should choose the grade of the magnetic rod according to the functional requirements. Functional requirements include two aspects – magnetic field strength and removal rate. Export products (such as APIs, food additives) generally require 12000 Gaussian field strength, and the removal rate is related to the number of strong magnetic bars or magnetic plates. The more layers, the higher the removal rate. If you only remove iron debris, you can choose a low-grade iron remover.

Third, According to the shape and fluidity of the material, the magnetic field structure of the iron remover is selected, mainly the magnetic rod and magnetic plate spacing. If the material is very fluid, use a rotating or vibrating magnetic rod.

Fourth, the material flux of the iron remover should be selected according to the production volume.

Fifth, Determine the three-dimensional size of the strong magnetic bar according to the on-site space where the iron remover is installed. Six also consider how the iron separator is connected to other production equipment.