Posts

What is the Magnet Strength of Magnetic Filter Bar?

Magnetic filter bar,Magnetic Rods,Magnetic Filter tube(Magnetic Separator) is extremely efficient at removing fine iron contamination from free flowing products such as sugar, grain, tea, flour, Plastic, liquid, granulate and any other type of powder with a low moisture content. As a result, your equipment and facilities will be safe and sound, and your products will be safe for consumption. This item can be supplied with any shape frame or studded end for easy of installation.

Per customers’ requirement. The highest is up to 12, 000GS (1.2T).

Following is the relationship between diameter, magnetic strength and Maximum Operation Temperature for reference:

| 0.25T | 0.5T | 0.7T | 0.9T | 1T | 1.1T | 1.2T | |

| Φ 19 (0.75″ ) | √ EH | √ EH | √ EH | √ H | √ M | – | – |

| Φ 22 (0.85″ ) | √ EH | √ EH | √ EH | √ H | √ M | √ N | – |

| Φ 25 (1.00″ ) | √ EH | √ EH | √ EH | √ SH | √ H | √ M | √ N |

| Φ 32 (1.25″ ) | √ EH | √ EH | √ EH | √ SH | √ H | √ M | √ N |

| Φ 38 (1.50″ ) | √ EH | √ EH | √ EH | √ UH | √ SH | √ H | √ M |

| Φ 50 (1.75″ ) | √ EH | √ EH | √ EH | √ UH | √ SH | √ H | √ M |

| Φ 76 (3.00″ ) | √ EH | √ EH | √ EH | √ UH | √ UH | √ SH | √ H |

| Φ 100(4.00″ ) | √ EH | √ EH | √ EH | √ UH | √ UH | √ SH | √ H |

Remarks:

(1).”√”means it can be manufactured on the condition of the diameters listed in the table.”- “means can not be manufactured.

(2). The related Max working temperature from different series.

H series: <=120

SH series: <=150

UH series: <=180

EH series: <=250

(3).Round and square are both available

(4). 304 and 316L stainless steel type are available

(5). Magnetic bar length can be custom made .Max length of is 2500mm when diamteter is 25mm.

(6). Various end design are available ,such as Nail head ,thread hole ,double screw bolt ,etc .

How to choose strong magnetic rods for the food industry?

Strong magnetic bar is a production equipment that guarantees the safety and quality of products. The ceramic industry and the food industry have been widely used and become one of the production equipments. The strong magnetic rod used in the pharmaceutical and food industries is a permanent magnet magnetic rod that does not require a power source.

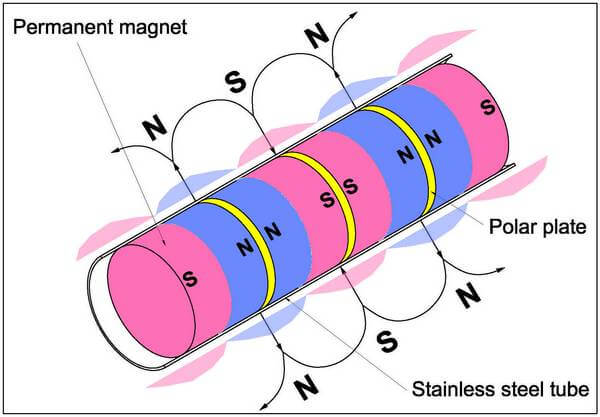

The basic principle is that when the iron-containing substance passes, it is attracted by strong magnetic force, and the iron-containing substance is firmly adsorbed on the pipe wall to ensure the integrity of the equipment and the safety of the product.

Divided from the structure, there are two kinds of strong magnetic rods, one is the process equipment connected with other production equipment, such as pipe iron remover, mixed iron remover, etc., the structure is relatively simple; one is the whole machine, such as rotary iron remover, Light powder iron remover. In addition, complete machines with composite functions, such as granulation and iron removal machines, screening and iron removal machines, etc., have appeared on the market.

From the technical function, the magnetic bar has a high, medium and low grade. The magnetic rod iron remover for assembling the magnetic rod with the ferrite magnetic material has the function of removing the ferromagnetic metal foreign matter, and the price is low, which is a low grade.

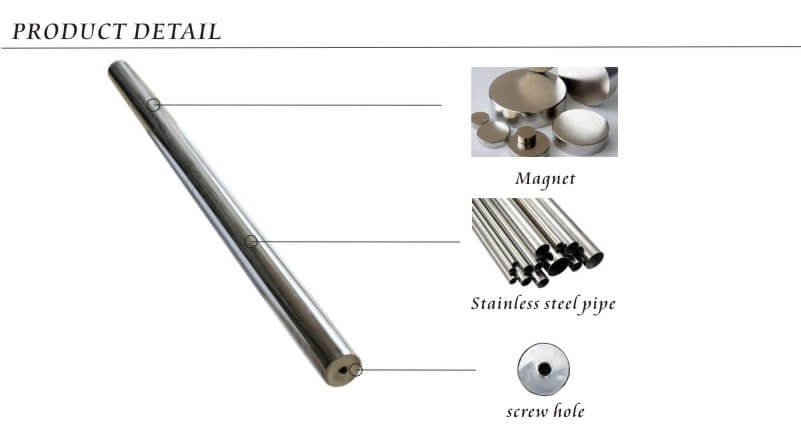

The magnetic rod is made of rare earth magnetic material, namely neodymium iron boron. NdFeB is divided into different series and grades according to its function. Mid-range iron remover generally uses N48 below NdFeB magnetic material, its field peak is 7000 to 10000 Gauss; Gaussian strong magnetic rod uses N48H, N50 or more magnetic material, the peak value of the table is as high as 12000 Gauss.

Magnetic bars are different from metal detectors. The strong magnetic rod is superior to the latter in that it can remove metal foreign matter in the production process, and the removal method is superior. In order to ensure the safety and quality of products, many large-scale enterprises use both products at the same time.

The selection of strong magnetic rods should be based on the actual and applicable cost requirements. First, it is necessary to determine whether to select process equipment or the whole machine according to the actual conditions of production;

Second, you should choose the grade of the magnetic rod according to the functional requirements. Functional requirements include two aspects – magnetic field strength and removal rate. Export products (such as APIs, food additives) generally require 12000 Gaussian field strength, and the removal rate is related to the number of strong magnetic bars or magnetic plates. The more layers, the higher the removal rate. If you only remove iron debris, you can choose a low-grade iron remover.

Third, According to the shape and fluidity of the material, the magnetic field structure of the iron remover is selected, mainly the magnetic rod and magnetic plate spacing. If the material is very fluid, use a rotating or vibrating magnetic rod.

Fourth, the material flux of the iron remover should be selected according to the production volume.

Fifth, Determine the three-dimensional size of the strong magnetic bar according to the on-site space where the iron remover is installed. Six also consider how the iron separator is connected to other production equipment.

How to Solve The Iron Slag Troubles For You?

The material will be mixed with a lot of iron impurities, which has become a headache for the manufacturers. To solve the problem of iron filings, Sinoneo magnetic bar providing reliable iron slag solutions and tailoring various strong magnetic bars.

The headache of the manufacturer is that the material is not clean and the product can not pass the quality inspection. This is a common problem.

This is the pain point of the manufacturers mentioned at the beginning of this article. Every time the iron products removed from the purchase can not filter the iron slag, the product can not pass the quality inspection, how to change the situation,so that It can reduce the production cost and quickly solve the problem.

It is necessary to mention the key points, how to find a good magnetic filter bar manufacturer!

Purchasing a strong magnetic bar not only depends on the price, but also on the quality! The low-priced strong magnetic bar, the magnet with the refurbished magnetic material or the magnetic core is not the same size, the strong NdFeB magnet is replaced by the ferrite magnet, which leads to the price of magnetic bar is different on the market.

How do you know the difference between good and bad magnetic bars?

Sinoneo Magnets magnetic bar manufacturers master to give you some suggestions:

First, starting from the appearance, how to weld the two ends of the magnetic bar, whether there is strict welding, can not enter the water, if found to be able to enter the water phenomenon, which means that this magnetic bar is not a good magnetic bar, can not be used.

Second, starting from the magnetic line, holding the magnetic rod to roll a few times in the ground, the magnetic line will come out, then you can use the Gauss meter to measure the magnetic force, confirm if you can meet your requirements.

Third, starting from the size of the specifications, using a special tool to measure the diameter of the strong magnetic bar has not reached the size of the order at the time, the deviation is not serious, these all indicate the strength of the manufacturer and the attitude of doing things.

Once you know this, go and tell your company’s purchasing staff, you have the ideas to reduce production costs and make the materials more pure.

Strong magnetic rod manufacturers: Sinoneo magnets focus on providing filter iron slag solutions, let us help you!

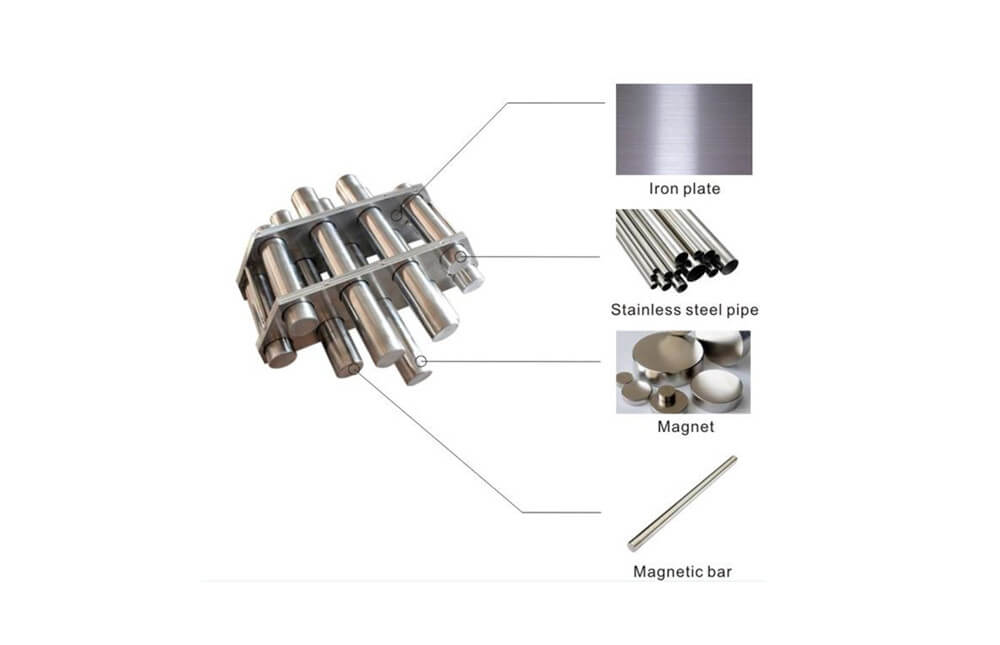

The details and common specifications of the magnetic grates(magnetic grids)

The magnetic grate(magnetic grid) is mainly used to remove iron impurities from the hopper, feed trough and floor space, which can effectively remove free flowing powder and iron impurities in small particles. The magnetic grate(magnetic grid) is equipped with a beautifully shaped and reasonably distributed magnetic bar that provides a high-intensity magnetic field to attract iron powder, iron filings, and other magnetically small pieces of metal in the flowing material.

The stainless steel seamless tube and the outer frame form a solid whole through the skilled welding of the workers. It can be installed on the production line or simply placed in a hopper, material box and easily removed and cleaned. The Sinoneo magnetic grate(magnetic grid) is made of materials with a corrosion-resistant surface that meets the cleanliness of food and even pharmaceuticals. Our magnetic grate(magnetic grid) is usually arranged in parallel with a center-to-center spacing of 50mm with a diameter 25mm magnetic bar.

The application of magnetic grate(magnetic grid):

Magnetic filter holder (magnetic frame) is mainly used to filter ferromagnetic impurities in powdery, granular raw materials and liquids or slurries. It is widely used in ceramics, electric power, mining, plastics, chemicals, rubber, pharmaceuticals, food, environmental protection, pigments. , dyes, electronics, metallurgy and other industries.

The working principle of magnetic grate(magnetic grid):

The magnetic filter grate(grid) is made of stainless steel tube and high value rare earth alloy NdFeB magnets. And combined on a fixed frame to form a magnetic filter holder. When the iron-containing substance passes, it is attracted by the magnetic rod, and the iron-containing substance is firmly adsorbed on the pipe wall to ensure the integrity of the equipment and the cleanness of the product.

The features of magnetic grate(magnetic grid):

The magnetic frame has no energy consumption and can be installed at any position on the production line that can be in contact with materials. It saves space and is easy to install. It mainly uses rare earth neodymium magnets as magnetic source, good magnetic force, simple structure and long working life. The style,size and shape can be customized according to customer requirements and production conditions.

The magnetic filter frame is mainly used to remove iron impurities from the hopper, feed trough and floor space, which can effectively remove free flowing powder and iron impurities in small particles. The magnetic grate(magnetic grid) has a well-packaged magnetic bar that provides a high-intensity magnetic field to attract iron powder, iron filings, and other magnetically small pieces of metal in the flowing material. It can be installed on the production line or simply placed in a hopper, material box and easily removed and cleaned.

The common specifications of magnetic grate(magnetic grid):

Single layer of pipe (9 pipe double layer) 300 x 40 (80) 6 pipe single layer (11 pipe double layer) 300 x 300 x 40 (80) 6 pipe single layer (11 pipe double layer) 350 x

40 (80) 7 single layer (13 tubes double layer) 350 x 350 x 40 (80) 7 tube single layer (13 tubes double layer) 400 x 40 (80) 8 tube single layer (15 tube double layer) 400 x 400 x 40 (80) 8 tube single layer (15 tube double layer) 450 x 40 (80) 9 tube single layer (17 tube double layer) 450 x 450 x 40 (80) 9 tube single layer (17 tube double layer) 500 x 40 (80) 10 tube single layer (19 tube double layer) 500 x 500 x 40 (80) 10 tube single layer (19 tube double layer)