Magnetic Properties of Neodymium Magnets:

| Grade |

Remanence |

Magnetic Induction |

Intrinsic Coercivity |

Max Magnetic Energy Product |

Maximum Working Temperature≤ |

| Br ( KG) |

Br (T) |

Hcb (KOe) |

Hcb (KA/m) |

Hcj (KOe) |

Hcj (KA/m) |

(BH)max(MGOe) |

(BH)max(KJ/m³) |

℃ |

| Max |

Min |

Max |

Min |

| N35 |

≥11.8 |

≥1.18 |

≥10.8 |

≥860 |

≥12 |

≥960 |

37 |

33 |

295 |

263 |

N |

≤80 |

| N38 |

≥12.3 |

≥1.23 |

≥10.8 |

≥860 |

≥12 |

≥960 |

39 |

36 |

310 |

287 |

| N40 |

≥12.7 |

≥1.27 |

≥11.0 |

≥876 |

≥12 |

≥960 |

41 |

38 |

327 |

302 |

| N42 |

≥13.0 |

≥1.30 |

≥11.0 |

≥876 |

≥12 |

≥960 |

43 |

40 |

343 |

320 |

| N45 |

≥13.3 |

≥1.33 |

≥11.0 |

≥876 |

≥12 |

≥960 |

46 |

42 |

366 |

335 |

| N48 |

≥13.7 |

≥1.37 |

≥10.5 |

≥836 |

≥12 |

≥960 |

49 |

45 |

390 |

358 |

| N50 |

≥14.0 |

≥1.40 |

≥10.5 |

≥836 |

≥12 |

≥960 |

51 |

47 |

406 |

374 |

| N52 |

≥14.2 |

≥1.42 |

≥10.5 |

≥836 |

≥12 |

≥960 |

53 |

49 |

422 |

390 |

| N54 |

≥14.4 |

≥1.44 |

≥10.5 |

≥836 |

≥11 |

≥876 |

55 |

51 |

438 |

406 |

| N35M |

≥11.8 |

≥1.18 |

≥10.8 |

≥860 |

≥14 |

≥1114 |

37 |

33 |

295 |

263 |

M |

≤100 |

| N38M |

≥12.3 |

≥1.23 |

≥11.0 |

≥876 |

≥14 |

≥1114 |

39 |

36 |

310 |

287 |

| N40M |

≥12.7 |

≥1.27 |

≥11.5 |

≥915 |

≥14 |

≥1114 |

41 |

38 |

327 |

302 |

| N42M |

≥13.0 |

≥1.30 |

≥11.8 |

≥939 |

≥14 |

≥1114 |

43 |

40 |

343 |

320 |

| N45M |

≥13.3 |

≥1.33 |

≥12.0 |

≥956 |

≥14 |

≥1114 |

46 |

42 |

366 |

335 |

| N48M |

≥13.7 |

≥1.37 |

≥12.2 |

≥972 |

≥14 |

≥1114 |

49 |

45 |

390 |

358 |

| N50M |

≥14.0 |

≥1.40 |

≥12.5 |

≥995 |

≥14 |

≥1114 |

51 |

47 |

406 |

374 |

| N52M |

≥14.2 |

≥1.42 |

≥12.5 |

≥995 |

≥14 |

≥1114 |

53 |

49 |

422 |

390 |

| N33H |

≥11.4 |

≥1.14 |

≥10.6 |

≥844 |

≥17 |

≥1350 |

35 |

31 |

279 |

247 |

H |

≤120 |

| N35H |

≥11.8 |

≥1.18 |

≥10.8 |

≥860 |

≥17 |

≥1350 |

37 |

33 |

295 |

263 |

| N38H |

≥12.3 |

≥1.23 |

≥11.0 |

≥876 |

≥17 |

≥1350 |

39 |

36 |

310 |

287 |

| N40H |

≥12.7 |

≥1.27 |

≥11.5 |

≥916 |

≥17 |

≥1350 |

41 |

38 |

327 |

302 |

| N42H |

≥13.0 |

≥1.30 |

≥11.8 |

≥940 |

≥17 |

≥1350 |

43 |

40 |

343 |

320 |

| N45H |

≥13.3 |

≥1.33 |

≥12.0 |

≥955 |

≥17 |

≥1350 |

46 |

42 |

366 |

335 |

| N48H |

≥13.6 |

≥1.36 |

≥12.2 |

≥971 |

≥17 |

≥1350 |

49 |

45 |

390 |

358 |

| N50H |

≥14 |

≥1.4 |

≥12.5 |

≥995 |

≥17 |

≥1350 |

51 |

47 |

406 |

374 |

| N52H |

≥14.3 |

≥1.43 |

≥12.5 |

≥995 |

≥17 |

≥1350 |

53 |

49 |

422 |

390 |

| N33SH |

≥11.4 |

≥1.14 |

≥10.6 |

≥844 |

≥20 |

≥1592 |

35 |

31 |

279 |

247 |

SH |

≤150 |

| N35SH |

≥11.8 |

≥1.18 |

≥10.8 |

≥860 |

≥20 |

≥1592 |

37 |

33 |

295 |

263 |

| N38SH |

≥12.3 |

≥1.23 |

≥11.0 |

≥876 |

≥20 |

≥1592 |

39 |

36 |

310 |

287 |

| N40SH |

≥12.6 |

≥1.26 |

≥11.5 |

≥916 |

≥20 |

≥1592 |

41 |

38 |

327 |

302 |

| N42SH |

≥12.9 |

≥1.29 |

≥11.8 |

≥940 |

≥20 |

≥1592 |

43 |

40 |

343 |

320 |

| N45SH |

≥13.2 |

≥1.32 |

≥12.0 |

≥955 |

≥20 |

≥1592 |

46 |

42 |

366 |

335 |

| N48SH |

≥13.6 |

≥1.36 |

≥12.2 |

≥971 |

≥20 |

≥1592 |

49 |

45 |

390 |

358 |

| N50SH |

≥14 |

≥1.4 |

≥12.5 |

≥995 |

≥20 |

≥1592 |

51 |

47 |

406 |

374 |

| N33UH |

≥11.4 |

≥1.14 |

≥10.6 |

≥844 |

≥25 |

≥1990 |

35 |

31 |

279 |

247 |

UH |

≤180 |

| N35UH |

≥11.8 |

≥1.18 |

≥10.8 |

≥860 |

≥25 |

≥1990 |

37 |

33 |

295 |

263 |

| N38UH |

≥12.3 |

≥1.23 |

≥11.0 |

≥876 |

≥25 |

≥1990 |

39 |

36 |

310 |

287 |

| N40UH |

≥12.6 |

≥1.26 |

≥11.5 |

≥916 |

≥25 |

≥1990 |

41 |

38 |

327 |

302 |

| N42UH |

≥12.9 |

≥1.29 |

≥11.8 |

≥940 |

≥25 |

≥1990 |

43 |

40 |

343 |

320 |

| N45UH |

≥13.2 |

≥1.32 |

≥12.0 |

≥955 |

≥25 |

≥1990 |

46 |

42 |

366 |

335 |

| N48UH |

≥13.6 |

≥1.36 |

≥12.2 |

≥971 |

≥25 |

≥1990 |

49 |

45 |

390 |

358 |

| N28EH |

≥10.4 |

≥1.04 |

≥9.50 |

≥756 |

≥30 |

≥2388 |

30 |

26 |

239 |

207 |

EH |

≤200 |

| N30EH |

≥10.8 |

≥1.08 |

≥9.50 |

≥756 |

≥30 |

≥2388 |

32 |

28 |

255 |

223 |

| N33EH |

≥11.4 |

≥1.14 |

≥10.6 |

≥844 |

≥30 |

≥2388 |

35 |

31 |

279 |

247 |

| N35EH |

≥11.8 |

≥1.18 |

≥10.8 |

≥860 |

≥30 |

≥2388 |

37 |

33 |

295 |

263 |

| N38EH |

≥12.3 |

≥1.23 |

≥11.0 |

≥876 |

≥30 |

≥2388 |

39 |

36 |

310 |

287 |

| N40EH |

≥12.6 |

≥1.26 |

≥11.5 |

≥916 |

≥30 |

≥2388 |

41 |

38 |

327 |

302 |

| N42EH |

≥12.9 |

≥1.29 |

≥11.8 |

≥940 |

≥30 |

≥2388 |

43 |

41 |

343 |

320 |

| N45EH |

≥13.2 |

≥1.32 |

≥12.0 |

≥955 |

≥30 |

≥2388 |

46 |

42 |

366 |

335 |

| N30TH |

≥10.8 |

≥1.08 |

≥9.50 |

≥756 |

≥35 |

≥2786 |

32 |

28 |

255 |

223 |

TH |

≤220 |

| N33TH |

≥11.4 |

≥1.14 |

≥10.6 |

≥844 |

≥35 |

≥2786 |

35 |

31 |

279 |

247 |

| N35TH |

≥11.8 |

≥1.18 |

≥11.0 |

≥876 |

≥35 |

≥2786 |

37 |

33 |

295 |

263 |

| N38TH |

≥12.2 |

≥1.22 |

≥11.0 |

≥876 |

≥33 |

≥2627 |

39 |

36 |

310 |

287 |

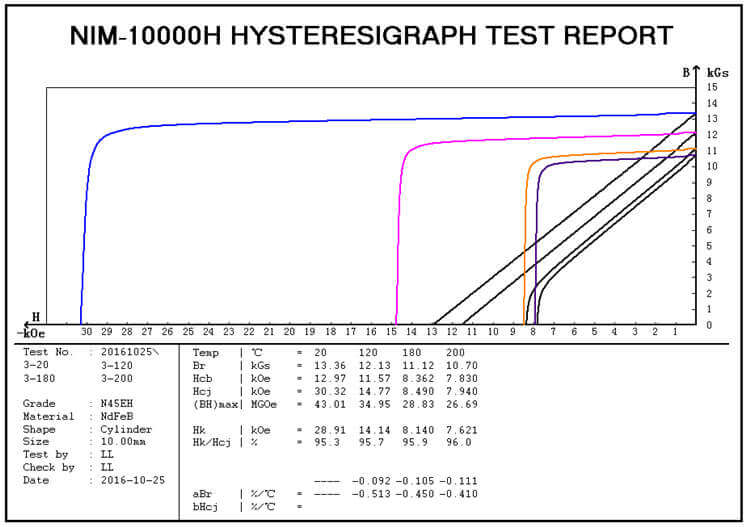

1. The above-mentioned data of magnetic parameters are given at room temperature.

2. The above-mentioned grades are our basic grades. We also have T (for instance 35SHT, etc.) and L-T (for instance L-38SHT, etc.) series grades which are derived from these basic grades. The main properties of the derived grades are corresponding to those of the basic grades.

3. The max working temperature, which the sampling specification(Permanent Magnet:φ10×7) to heat up to the regular temperature for the lay of a long time(general 1000H.). Then take this sampling to cool attained room temperature. The irreversible loss of magnetic flux is less than 5%, This max keeps temperature definiteness which is the permanent material should be accepted by the max temperature. The sign: Tw, The unit: Kor ℃

The maximum working temperature of the magnet is changeable due to grade, operating point, coating, and environmental factors.

Chemical Composition of Neodymium Magnets:

Chemical analysis for sintering NdFeB magnets material based on intermetallic compounds RE2Fe14B,main composition is NdFeB magnet is (RE), (Fe) (B),thereinto thulium (Nd), in order to obtain different performance can instead by thulium of (Dy),(Pr) etc. also other metal can instead Fe,for example (Co), (Al) etc., smaller content of boron, but it affect tetragonal crystal intermetallics, making the intermetallics with high magnetization,uniaxial anisotropy and curie temperature.

Physical Properties of Neodymium Magnets:

| Temp.Coeff.of Br |

-0.11%/ °C |

Temp.Coeff.of Hc |

-0.60%/ °C |

| Density |

7.3-7.5g/cm 3 |

Electrical Resistivity |

114 .cm |

| Vickers Hardness |

600Hv |

Flexural Resistivity |

25kg/mm |

| Tensile Strength |

8.0Kg/mm2 |

Coeff. Of Thermal Expansion |

4X10 -6 / °C |

| Specific Heat |

0.12Kcal/Kg |

Thermal Conductivity |

7.7kcal/[m.h. °C |

| Young ¡s Modulus |

1.6X10[11]N/m2 |

Rigidity |

0.64N/m2 |

| Poisson¡¯s Ratio |

0.24 |

Compressibility |

9.8×10-12m2/N |

| Curie Temperature |

310-340 °C |

|