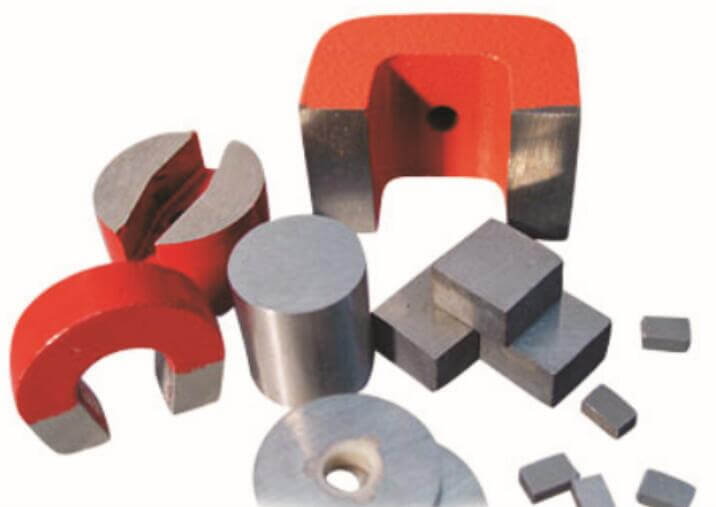

ALNICO MAGNETS

Permanent Alnico Magnets,Sintered Alnico Magnets,Cast Alnico Magnets

AlNiCo is a term referring to a series of permanent magnet alloys which in addition to iron are composed primarily of aluminum (Al), nickel (Ni), and cobalt (Co). The development of alnico began in 1931 when T. Mishima in Japan discovered that an alloy of iron, nickel, and aluminum had a much higher coercivity than the best steel magnets of the time. The composition of alnico alloys is typically 8–12% Al, 15–26% Ni, 5–24% Co, up to 6% Cu, up to 1% Ti, and the balance is Fe.

Various Alnico grades with differing magnetic properties are achieved by modifying the chemistry and manufacturing process. For example, specialized casting techniques are used to achieve the unique crystalline grain orientation found in the Alnico 5-7 grade.

Before the development of rare earth magnets in the 1970s, Alnico was the strongest type of permanent magnet. In many applications, Alnico has been replaced by other types of magnets. However, the temperature stability of Alnico magnets, and the fact that they can be used in very high temperatures, up to 500C, make them indispensable in certain applications.

Typical magnetic properties of Cast Alnico magnets:

| Grade | Br | HcB | Hcj | (BH)max | Br | Hcj | Max Temp | MMPA Equivalents |

||||

| KGs | mT | kOe | Ka/m | kOe | Ka/m | MGOe | Kj/m³ | TK(Br)%/K | TK(Hcj)%/K | ºC | ||

| ISOTROPIC CAST ALNICO MAGNETS | ||||||||||||

| LN10 | 6.5 | 650 | 0.48 | 38 | 0.5 | 40 | 1.25 | 10 | -0.035 | -0.025 | 450 | ALNICO3 |

| LNG12 | 7.5 | 750 | 0.56 | 45 | 0.58 | 46 | 1.5 | 12 | -0.03 | -0.02 | 450 | ALNICO2 |

| LNGT18 | 5.5 | 550 | 1.13 | 90 | 1.21 | 97 | 2.25 | 18 | -0.025 | 0.01 | 550 | ALNICO8 |

| ANISOTROPIC CAST ALNICO MAGNETS | ||||||||||||

| LNG34 | 11 | 1100 | 0.63 | 50 | 0.65 | 52 | 4.25 | 34 | -0.02 | 0.01 | 525 | ALNICO5 |

| LNG37 | 11.8 | 1180 | 0.61 | 49 | 0.64 | 51 | 4.63 | 37 | -0.02 | 0.01 | 525 | |

| LNG40 | 12 | 1200 | 0.63 | 50 | 0.65 | 52 | 5 | 40 | -0.02 | 0.01 | 525 | |

| LNG44 | 12.5 | 1250 | 0.65 | 52 | 0.68 | 54 | 5.5 | 44 | -0.02 | 0.01 | 525 | |

| LNGT34 | 11.5 | 1150 | 0.73 | 58 | 0.75 | 60 | 3.5 | 28 | -0.02 | 0.03 | 525 | ALNICO6 |

| LNG52 | 13 | 1300 | 0.7 | 56 | 0.73 | 58 | 6.5 | 52 | -0.02 | 0.03 | 525 | ALNICO5DG |

| LNG60 | 13.5 | 1350 | 0.73 | 58 | 0.75 | 60 | 7.5 | 60 | -0.02 | 0.03 | 525 | ALNICO5-7 |

| LNGT38 | 8 | 800 | 1.38 | 110 | 1.4 | 112 | 4.75 | 38 | -0.025 | 0.01 | 550 | ALNICO8 |

| LNGT40 | 8.5 | 850 | 1.44 | 115 | 1.46 | 117 | 5 | 40 | -0.025 | 0.01 | 550 | |

| LNGT44 | 9 | 900 | 1.44 | 115 | 1.46 | 117 | 5.5 | 44 | -0.025 | 0.01 | 550 | |

| LNGT36J | 7.2 | 720 | 1.88 | 150 | 1.9 | 152 | 4.5 | 36 | -0.025 | 0.01 | 550 | ALNICO8HC |

| LNGT60 | 10 | 1000 | 1.38 | 110 | 1.4 | 112 | 7.5 | 60 | -0.025 | 0.01 | 550 | ALNICO9 |

Typical magnetic properties of sintered Alnico magnets:

| Grade | US Standard | Br | Hcb | (BH)max | Tc | Tw | T.C.α(Br) |

| mT/Gs | kA/m/Oe | kJ/m3/MGOe | ℃ | ℃ | %/℃ | ||

| FLN8 | S.ALNICO3 | 500/5000 | 40/500 | 8/1.00 | 760 | 450 | -0.022 |

| FLNG12 | S.ALNICO2 | 700/7000 | 48/600 | 12/1.50 | 810 | 450 | -0.014 |

| FLNGT18 | S.ALNICO7 | 600/6000 | 90/1130 | 18/2.20 | 860 | 450 | -0.02 |

| FLNG34 | S.ALNICO5 | 1200/12000 | 48/600 | 34/4.25 | 890 | 450 | -0.016 |

| FLNGT28 | S.ALNICO6 | 1050/10500 | 56/700 | 28/3.50 | 850 | 450 | -0.02 |

| FLNGT38 | S.ALNICO8 | 800/8000 | 120/1500 | 38/4.75 | 850 | 450 | -0.02 |

| FLNGT42 | S.ALNICO8 | 880/8800 | 120/1500 | 42/5.25 | 820 | 450 | -0.02 |

| FLNGT33J | S.ALNICO8HC | 700/7000 | 140/1750 | 33/4.13 | 850 | 450 | -0.025 |

Manufacturing Process of Alnico Magnets:

Alnico magnets are manufactured either by casting or sintering. Alnico is produced by conventional foundry methods using resin bonded sand molds or powder metal manufacturing methods. Sintering Alnico is suitable for complex geometries.

Most Alnico produced is anisotropic meaning that the magnetic axle of the grains is oriented in one direction. The orientation is achieved by a heat treatment process after casting or sintering. The process involves heating the casting or sintered part above its Curie Temperature and then cooling it at a controlled rate in the presence of a directionalized magnetic field. The final shaping of the Alnico materials is achieved by abrasive grinding and cutting where close tolerances are required.

Process Flow: Raw Material—–Mixing—Melting—–Heat Treatment—–Magnetic Testing—-Grinding—–Inspection—–Packing and Shipping

Applications of Alnico Magnets:

1) Inner magnetic voltmeter/ammeter, measuring instrument, avometer, flow meter.

2) Magnetic sensors, polarized relay, temperature, and pressure controller.

3) Buzzer of mobile phone, hearing aids, mini speaker

4) Lighter of the automobile, the odometer of automobile and motorcycle, permanent motor, adsorptive appliance

5) Widely applied in high stability field as aviation, space flight, and military technology

In addition, due to the good corrosion resistance characteristic, non-coating is needed for surface protection.

Surface Treatment of Alnico Magnets:

Alnico magnets are not prone to corrosion and can normally be used without any surface protection. In some applications, however, a smooth surface is preferred.. Sinoneo can provide customers with high-quality coatings and plating of Zinc, Tin, Nickle, Epoxy, etc.

During the process of coating and plating, Sinoneo attaches great importance to environmental protection, all coating meets the requirements of ROHS and RECH.

| Coating | Code | Color | Minimum Local Thickness |

Merge etching time | Working temperature | |||

| Neutral salt Spray test |

Humid heat test | Pressure Vessel test |

||||||

| Ni(Barrel plating) | Ni | Sliver | 10 | 24 | 300 | 48 | <200 | |

| Ni(rack plating) | Ni | Sliver | 10 | 8 | 300 | 48 | ||

| NiCuNi(barrel plating) | NiCuNi | Sliver | 10 | 72 | 500 | 48 | ||

| NiCuNi(rack plating) | NiCuNi | Sliver | 10 | 48 | 500 | 48 | ||

| Zinc | White zinc | Zn | White Zinc | 4 | 24 | 48 | / | <170 |

| Color zinc | CZn/Zn | Color Zinc | 6 | 48 | 48 | / | ||

| Chemical plating Ni | Ni | Silver | 12 | 96 | 500 | 48 | <200 | |

| Electrophoresis epoxy | Epoxy | Black,grey | 10 | 48-96 | 120 | 0-24 | <130 | |

| Parylene | Parylene | Colorless and transparent | 12.7-25.4 microns Meet the MIL-I-46058C standard |

48 | / | / | <130 | |

To offer you our Alnico magnets price, please offer the following details:

Magnets grade.

Magnets size: As the drawing

Magnetism direction: Which direction to oriented The north pole and south pole

Magnets coating: Without Coating, Nickel, Zn, Black Epoxy, Ag, Au, etc.

Quantities: More mass order quantities.More Lower the prices.